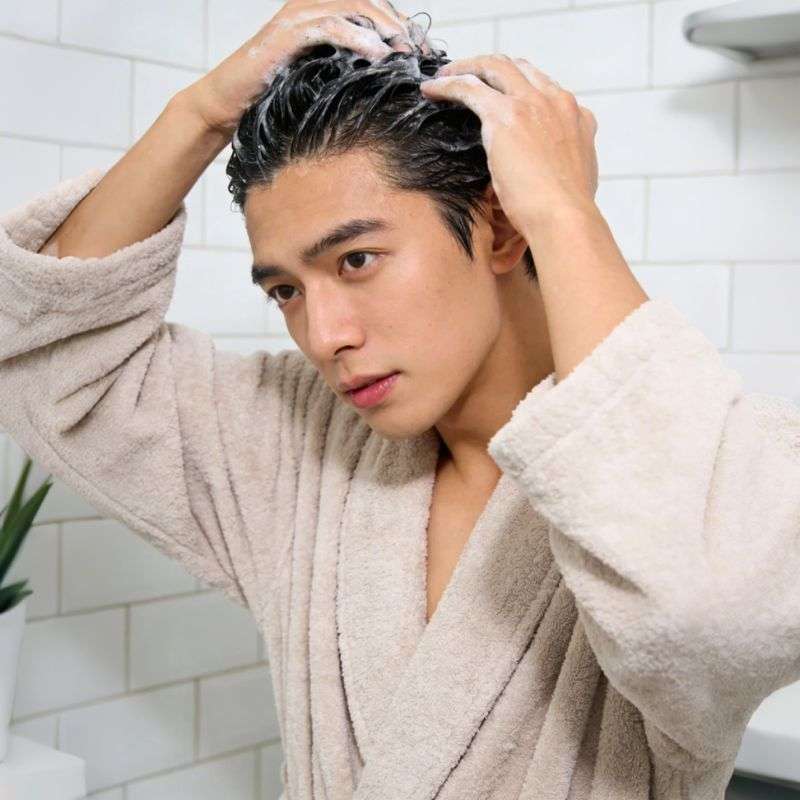

When you are planning to launch your private label hair care products, choosing a reliable hair care product manufacturer is crucial. As a brand, you may be faced with such a puzzle: OEM factories with the same price, why do some produce products with excellent stability, while others frequently have quality problems? The answer lies in the factory’s quality control capabilities.

Why Is Quality Control at the Heart of Choosing an Oem/Odm Foundry?

The quality of hair care products directly affects the consumer experience and brand reputation. A bottle of shampoo that is layered, discolored, or of substandard efficacy not only leads to customer loss, it can also pose a compliance risk. Especially when you are facing the Middle East, Southeast Asia and other B-end markets, local regulations have strict requirements for the safety of cosmetics, ingredient labeling, etc.

Excellent hair care product manufacturers can ensure the stability of each batch of products through strict quality control, and a factory without a system may produce a hair mask today with amazing effects, but the same formula will have a texture difference next month. This uncertainty is fatal for brands.

Evaluate the 5 Core Dimensions of Foundry Quality

1.Factory qualification and certification

Professional OEM/ODM manufacturers will take the initiative to show certification qualifications, which is the most basic trust endorsement. Focus on the following:

- International certification: e.g. ISO 22716 (Cosmetic GMP), GMPC, FDA registration (for the US market)

- Regional compliance: For example, SASO certification is required in the Middle East and ASEAN GMP standards are required in Southeast Asia

- Production license: Check the factory’s business license, cosmetic production license, etc

For example, LocRoyal, which specializes in customized hair care products, not only has ISO 22716 and GMPC dual certification, but also completed FDA registration, which means that its hair care essential oils, hair masks and other products can directly enter the Middle East market, saving brands a lot of compliance costs.

2.Raw material supply chain

A customer once complained that the same cocamide formula, a foundry made shampoo cleaning power is obviously insufficient. It was later discovered that the factory had secretly changed suppliers of low-cost raw materials in order to reduce costs. Therefore, when evaluating an OEM hair care provider, it is important to look at:

- Supplier background: Do you cooperate with BASF, Evonik and other international raw material suppliers? What is the proportion of imported raw materials?

- Traceability system: Can you provide COA (Component Analysis Report) and batch trace records for raw materials?

- Stock management: Is there a safe stock of key ingredients (e.g. Moroccan argin) to avoid temporary replacement?

LocRoyal’s raw materials are mainly imported from: internationally renowned raw material suppliers (France, Canada, South Korea, Japan, Morocco, etc.), from raw material selection to finished product packaging have undergone strict quality testing.

3.Production flow control

When visiting the factory, it is recommended to focus on the following aspects:

- Degree of automation: The automatic filling line can control the capacity error of the conditioner within ±1 gram, while the manual filling may differ by ±5 grams.

- Environmental control: Does the dust-free workshop meet the 100,000 standard? Is the temperature and humidity of the emulsion workshop monitored in real time?

- SOP execution: Does the operator sterilize and weigh in strict accordance with the procedures? Is there a double check in the feeding process?

We compared the production sites of two OEM factories: Factory A, where workers pick caps directly by hand, and Factory B, where visual recognition systems are used to automatically remove defective products – the latter naturally has a lower defect rate.

4. Inspection system

Quality hair care manufacturers set up multiple inspection levels:

- Raw material admission test: Reject the essence of excessive microorganisms

- Semi-finished product testing: check pH value, viscosity and other indicators after emulsification

- Complete inspection of the finished product: including stability test (high temperature/freezing cycle), efficacy verification, etc

5. Customer cases and market reputation

Quickly judge the strength of the plant through three questions:

- Partner brands: Have you ever worked for a well-known hair care brand? Such customers usually have strict inspection standards

- Market coverage: Has the product entered the target market (such as the Middle East, Europe and America)?

- Crisis Management: Ask how quality disputes have been resolved in the past, and how fast is the response?

The speed and execution of feedback and problems are far more important than the low price.

Practical Advice for Brands

- On-site factory inspection: do not just look at PPT, personally check the workshop health conditions, equipment maintenance records

- Test sample: 3 different batches of similar products are required to compare the consistency

- Small order trial production: First place 500-1000 pieces of trial order to test the actual delivery capacity of the factory

Why Locroyal Is the Oem/Odm Partner of Choice for Many Brands?

Having worked in the cosmetics foundry industry for many years, we know that quality is the ultimate principle. LocRoyal not only has ISO 22716 and GMPC certification, but also applies these standards to the production every day – from raw materials into the factory to finished products out of the warehouse, every step can withstand the most stringent inspection.

We’re very picky when it comes to ingredients. Choosing only internationally renowned raw material suppliers, such as France, Canada and other high-quality ingredients from the world, is like Michelin restaurants choosing only the freshest ingredients. Each batch of raw materials has an “ID card”, which can check the source and test report at any time, so that you can rest assured.

Walk into our factory and you will see more than 30 automation machines working in an orderly manner. Siemens’ intelligent system acts as a “supervisor”, keeping an eye on the ratio of ingredients and alerting if there is a slight deviation. The emulsification capacity of 150 tons per day can meet the needs of large orders and ensure that each batch of products maintains a consistent high quality.

What we are most proud of is our customized service. Looking to develop nourishing essential oils for the Middle East? Southeast Asia’s favorite cool shampoo? Or the pure formula popular in Europe and America? Our research and development team is ready to help you achieve everything from a single product to a complete series. After all, differentiation is the key to success in this highly competitive market.

Choosing LocRoyal is to choose a partner who understands the product and the market better. We are not only a foundry, but also a solid backing for your brand development.

Conclusion

Choosing a hair product manufacturer is like choosing a marriage partner – the initial cost is not the only consideration, the long-term stable “experience” is the key. Through the comprehensive evaluation of the 5 dimensions of qualification, supply chain, production, testing and reputation, you will be able to find the quality foundry that makes the brand worry and consumers feel at ease.

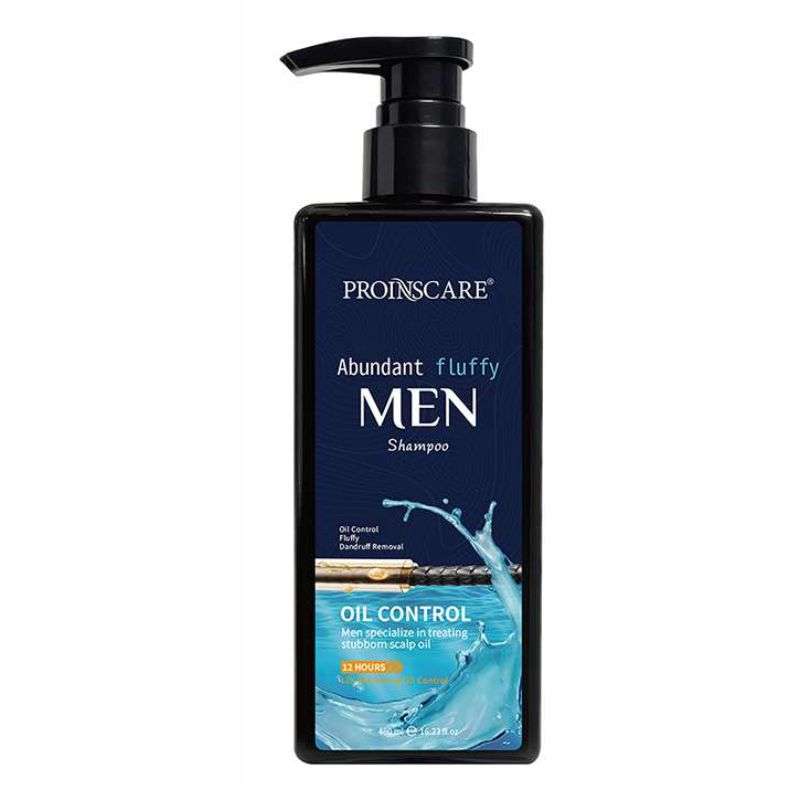

LocRoyal is a professional hair care manufacturer, we have our own brand ” PURC ” and “PROINSCARE”, can offer private label hair care products customization service.

FAQ

What types of private label hair care products can LocRoyal produce?

We offer a comprehensive range of hair care product solutions, including shampoo, conditioner, hair mask, hair care essential oil, scalp care and other products, supporting full category customization from basic cleaning to professional care.

As a hair care product manufacturer, how does LocRoyal ensure the quality and stability of its products?

We use Siemens intelligent production system, 30+ sets of automation equipment to ensure accurate matching, with raw material batch traceability and three-level quality inspection system, to ensure the quality of each bottle of products is consistent.

What’s the MOQ for OEM?

Normally depends on bottle type, different bottle, different MOQ.We have cooperated with many bottle suppliers, can offer both high and low MOQ.

How long the production time of private label?

After confirming design, around 30~40 days.