LocRoyal’s In-Depth Analysis of Whole-Process Quality Control from Raw Materials to Finished Products

Have you ever used a skincare or hair care product and wondered why some feel amazing while others don’t live up to the hype? The brand name is not the secret to great products; it is the process of quality check that takes place in the background.

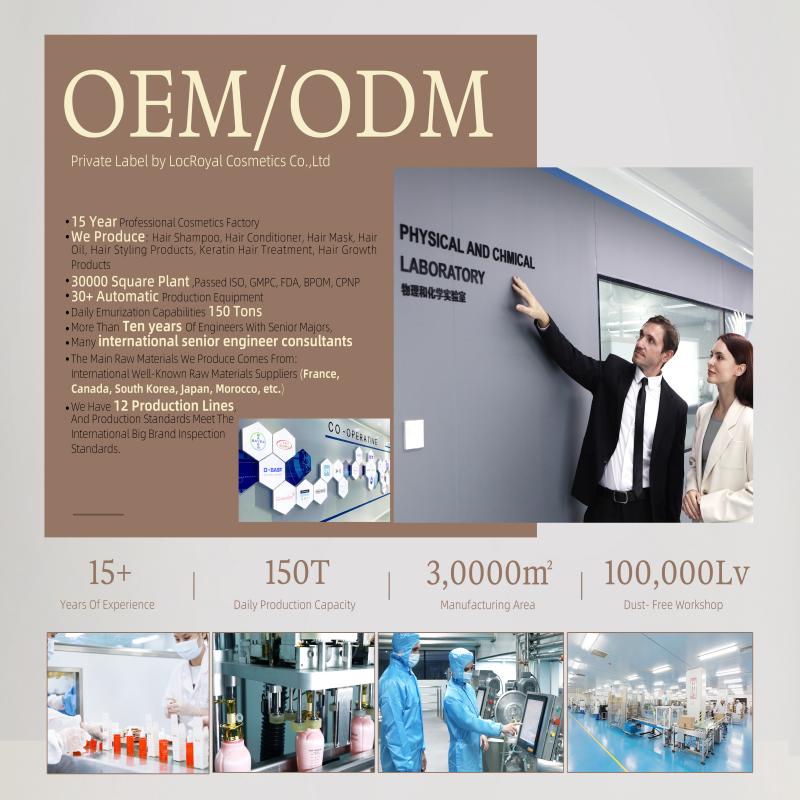

There is nothing more paramount for the brands within OEM or ODM cosmetics than product quality. Customers always look for the safety, efficiency, and reliability of products in the market. If the ingredients of a particular product are not consistent or the packaging is not up to standard then it can cause a brand negative impact. This is why it is so crucial to make the right decision and select the appropriate cosmetics factory to cooperate with.

Here at LocRoyal Cosmetics, quality assurance constitutes one of our primary corporate values. Right from the selection of ingredients and packaging the products, you are guaranteed that everything is as excellent. But how exactly do we do that? Let’s go step by step.

It All Starts with High-Quality Ingredients

Like any other thing on the market, cosmetic products also start with good raw materials. If the ingredients are not safe, effective, or consistent, it will be very difficult to have a safe, effective, or consistent final product in the market.

1. Sourcing Ingredients from Trusted Suppliers

To ensure that only the best quality products are being produced, we take pride in partnering with the right suppliers from around the globe. Many of the ingredients we use are imported from France, Canada, South Korea, Japan, and Morocco, which are top nations in the field of skin and hair care research.

All our suppliers are reliable and reputable; all the products are safe for all skin and hair types globally.

2. Testing Ingredients for Safety and Effectiveness

When given any ingredient, the first procedure is to check its qualities to ensure that it meets our recommended quality. Our tests include:

Ingredient Analysis: This is about ensuring that the ingredients in the compound are in the correct proportion as required or recommended.

Microbial Testing: This is a test that examines bacteria, mold, or any other microorganisms that are dangerous to the health of an individual.

Heavy Metal Testing: Make sure that no toxic substances such as lead or mercury are being used in the tested samples.

Stability Testing: Exposing the ingredient to conditions realistic to storage to check for its performance over time.

3. Making Sure Ingredients Are Always Available

As essential as a good product is, more important is the capacity to produce it at regular intervals. In order to ensure that we have an adequate supply of the ingredients at all times:

- Work with multiple suppliers to avoid shortages.

- Use intelligent inventory systems to track stock levels and plan ahead.

Since all these are quality inputs and if our supply chain management is equally good, it’s time to take the next steps in preparation and put these inputs into the production of the finished products.

Using Smart Manufacturing to Reduce Mistakes

As much as it is essential to source the finest ingredients, it will not be beneficial if the preparation process is not well done. This is why we employ sophisticated technologies in manufacturing, so as to ensure every manufactured product from our company is well produced.

1. Keeping the Production Area Clean and Safe

Hygiene plays a critical role since contamination can occur in a dirty environment, explaining why our cleanroom complies with GMPC. Some additional measures we follow that enable making the environment sterile include:

- Filtering systems that help to eliminate dust and any other particles in the air

- Use of ultraviolet light to eliminate bacteria and other germs.

- Measures of personal protective gear worn by the workers to minimize contact with dangerous contaminants.

2. Using Machines to Improve Accuracy

To ensure that each product that is produced is uniform, the required manufacturing equipment has been integrated to auto-operate. Some of the machines include the following:

- Automated weighing machines that measure ingredients exactly.

- Siemens intelligent feeding systems that mix ingredients precisely.

- Automatic filling, capping, and sealing machines that ensure each product is packaged correctly.

3. Large-Scale Production for Any Order Size

We are able to offer small batch in addition to large-quantity production orders as well. As a company with 12 production lines with a production capacity of 150 tons per day, we are capable of manufacturing products in different capacities.

But how can we be so certain that each run through the batch II process meets such a high standard? This is where the concept of quality testing comes in.

Checking Every Product for Quality and Safety

Absolutely best ingredients are used along with using the highly advanced machines but still, we have to make sure that all the batches are perfect.

1. Following International Safety Standards

Some of the safety standards we observe in our products are as follows;

- ISO (International Organization for Standardization)

- GMPC (Good Manufacturing Practice for Cosmetics)

- FDA (Food and Drug Administration, USA)

- BPOM (Indonesian Food and Drug Authority)

- CPNP (Cosmetic Products Notification Portal, EU)

This makes our products safe to be administered to the international market and ensures they adhere to all international quality standards.

2. Testing Products at Every Stage

During production, we perform real-time monitoring to identify errors in the production process. We also:

- Test semi-finished products to make sure the formula is correct before final packaging.

- Check the final product for safety, consistency, and performance.

3. Keeping Samples for Future Quality Control

Retention of samples is done for each batch for a period of 3 years. This way, we guarantee that subsequent orders will resemble previous ones in terms of quality so as not to impact a brand’s reputation negatively.

Now that the products are already created and tested it is important to package them well.

Packaging That Protects the Product and Looks Great

Packaging does not only beautify the product but also protects the formula and guarantees that the customer receives it in its best form.

1. Using Durable, High-Quality Packaging

Some of the key characteristics are checked in our packaging materials to ensure that it complies with the following:

- Strong enough to prevent damage during shipping.

- Resistant to temperature changes that could affect the product inside.

- Eco-friendly, following environmental safety guidelines.

2. Using Automated Packaging Inspections

In order to minimize on errors, we implement automated packaging equipment, which will include features such as:

- To ensure that each bottle has the right volume of the product

- Sealing quality to prevent leaks and contamination.

3. Final Inspections Before Shipping

In order to ensure that only the best products are delivered to the customer, every product is subjected to a quality check before it is shipped out.

Now the products are packed, how can they be delivered to the customers at a specific time?

Managing the Supply Chain for Fast and Reliable Delivery

Irrespective of the quality of the product being offered, if it is delivered late or is in the wrong condition, it will not sell. That is why we are concerned with the delivery of our goods within the shortest time possible.

1. Ensuring On-Time Delivery

We make shipment of our products on a daily basis so that our international clients get their consignments on time.

2. Flexible Production Options

We offer:

- Small-batch production for startups and new brands.

- Large-scale manufacturing for established brands.

- Custom formula development based on market trends.

With flexible supply chain and production capability, we expand and enable the growth of many brands.

How to Choose the Right OEM/ODM Manufacturer

Unfortunately, not all OEM/ODM producers guarantee that they employ good quality practices. The following are some of the questions that you should ask when you are looking for the cosmetics factory to deal with:

✅ Is it an ISO and other security certification from the international market?

✅ Do they use high-quality, tested ingredients?

✅Do they use automated manufacturing to ensure consistency?

✅ Do they test products at every stage of production?

✅ Do they have a stable supply chain to avoid delays?

At LocRoyal, we check all these boxes.

Partner with LocRoyal Cosmetics Today

Are you searching for a reliable private label hair care products manufacturing company? We use intelligent production, technical standardization, and mechanized processes to achieve a high standard of production for cosmetics.

Visit LocRoyalHairCare.com to learn more.

LocRoyal is a professional hair care manufacturer, we have our own brand ” PURC ” and “PROINSCARE”, and can offer private label hair care products customization services.

FAQs

1. What is the difference between OEM and ODM in cosmetics?

OEM involves the actual production of products using the formula of a client, while ODM consists of the new formulation of products and the brands under which these products will be sold. Both options allow businesses to sell high-quality beauty products under their own label.

2. How do I choose a reliable hair care manufacturer?

A trustworthy hair care manufacturer should follow intelligent manufacturing processes, use high-quality ingredients, and meet international standards. Look for a cosmetics factory with GMP and ISO certifications.

3. What are private label hair care products?

Private label hair care products are pre-developed formulas that brands can customize with their own packaging and branding. This is a cost-effective way to launch a beauty line.

4. Can I order wholesale products from a cosmetics supplier?

Yes! A cosmetics supplier provides B2B clients with wholesale products, including cosmetics customization options for personalized branding.

5. Why is intelligent manufacturing important in the cosmetics industry?

Intelligent manufacturing improves efficiency, ensures consistency, and reduces errors in hair care product manufacturer production lines, leading to better-quality products.