Do you ever wonder how the shampoo, conditioner, or hair serum you use is manufactured? It is a more complex process than just combining the ingredients to produce the final hair care product. Manufactured goods run through preproduction, production, postproduction, and distribution channels before getting to the shelf.

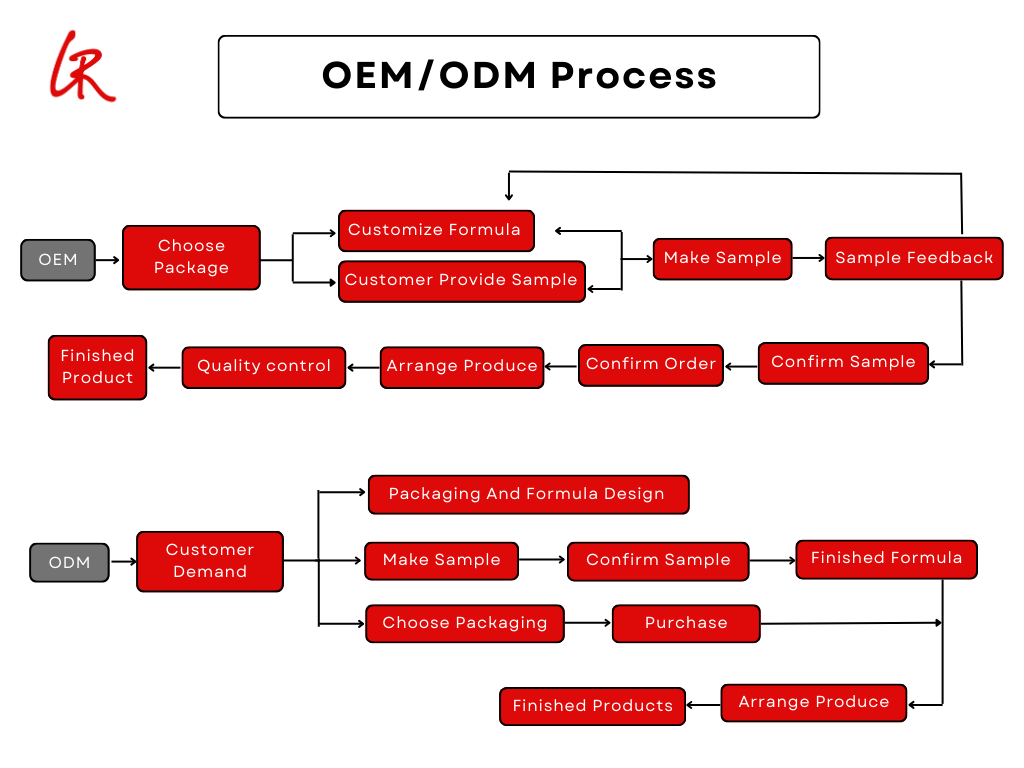

If a hair care product business is in an initial stage and wants to develop its own hair care products, it is advisable to contact a hair care product manufacturing company. This way, through OEM/ODM facilities, the brands are able to create privately labeled hair care products with no need to establish a factory on their own. These services are beneficial in the sense that they eliminate many inconveniences that are usually required by companies that wish to introduce new products in the market with high standards in terms of quality and novelty.

However, what does the process look like from the backstage? Thus, we need to determine the steps that would guarantee every bottle of shampoo and conditioner sold meets the customers’ expectations. In this article, the hair care product manufacturer and processing details shall be discussed in detail, starting from the acquisition of raw materials and ending with the final distribution phase.

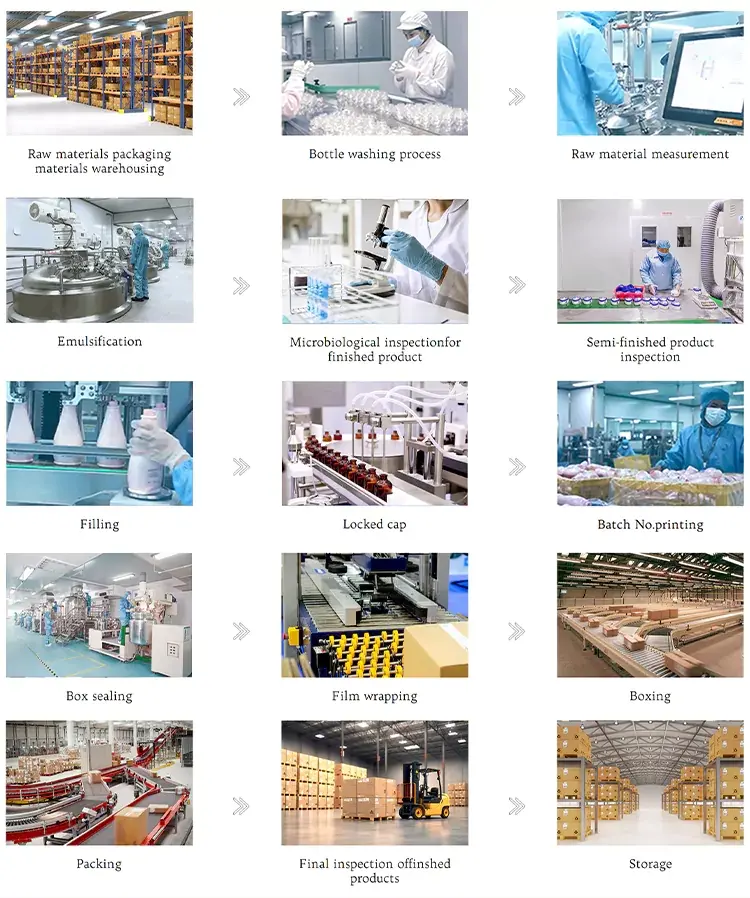

1. Raw Material and Packaging Material Management

The process of developing a hair care product goes way beyond the actual preparation of the product up to the time it is packed in the container. The first process between the production function is identifying and sourcing of raw materials and packaging materials. Each time preparing hair-related products, a professional hair care manufacturer has to ensure that each ingredient and container must pass quality inspection first.

Warehouse Management for a Steady Supply

It is essential to have a proper manufacturing warehouse for the proper operation of the manufacturing process and for efficiently achieving the desired goals. The supplies and packaging of hair care products must be properly stored to avoid spoiling them or even degrading the ingredients used in making the hair care products.

Temperature and humidity levels are checked to warrant that the raw materials are fresh and effective. For instance, a raw material that is commonly used in promoting custom hair care products – essential oil – should be stored in a cool and dark environment to ensure that the product does not lose its effectiveness. Like any other bottles, plastic bottles and jars require proper storage to eliminate issues of deformation or damage.

Manufacturers should ensure that their inventory is adequately stocked and stored in the right place so as to avoid any interruptions of their supply chain and hampering their production.

Raw Material Testing for Safety and Effectiveness

It is mandatory for every raw material to undergo what is referred to as Raw Material Testing to ascertain the efficacy and safety of the ingredient. This is a sure way of ensuring that the products in the market are of acceptable quality.

- This is done by purity tests, which seek to determine certain unwanted elements, such as heavy metals or other chemicals, that may cause harm to the body.

- Microtests can be used to determine if the ingredients are sterile or are containing bacterial spat, mold or yeast formation.

- Stability tests reveal how an ingredient performs in relation to various changes in conditions, be it heat or humidity, etc.

These tests are important in ensuring that the final product is optimally safe and that it is as effective as needed in solving its intended purpose. A product can only proceed to the next level, which is preparation for production after all the raw materials have to undergo various quality inspection tests.

2. Preparation Before Production

Once all materials are approved, the next step in the hair care product process is preparing them for production. This involves thorough cleaning and precise measurement of ingredients to ensure consistency and safety.

Bottle Cleaning: Ensuring No Contamination

Each receptacle, bottle, jar, or other vessel used to hold the product must first be thoroughly washed. Even if they arrive from a trusted supplier, tiny particles of dust or bacteria could be present.

Manufacturers use advanced purification systems to ensure that all containers are completely sterile. Some common cleaning methods include:

- Hot water rinsing: Wash with hot water, especially to eliminate dust and debris that may be present on the dishes.

- UV light sterilization: These are a few things you will have to do to ensure that the bacteria present are killed by UV light sterilization.

- Proposed drying methods that would prevent re-contamination from affecting the final product include air drying in a cleanroom environment.

In this sense, by properly cleaning packaging, the manufacturers minimize possible contamination that may have an unfavorable influence on the product.

Measuring Ingredients for Consistency

It is therefore proper to say that, in order to have quality products in the end, the ingredients that are used in making the products should be measured properly. When measurement is done incorrectly, it leads to an unstable as well as non-efficient product.

For instance, applying a high volume of moisturizing oils to a conditioner might result in a slippery feel. On the other hand, if the appropriation of conditioning agents is inadequate, then the product does not afford enough hydration.

With the help of sophisticated Hair Care Formulation Development strategies, it is ascertained that each ingredient is included perfectly.

Now that everything is cleaned and measured, it’s time to start making the product!

3. Core Production: Turning Ingredients into Hair Care Products

This is the most crucial stage of the hair care production process since it is the moment when the ingredients are processed and turned into the final product.

Emulsification Technology for a Smooth Texture

Emulsification technology is one of the most crucial processes in the Hair Care Formulation Development. This procedure involves the incorporation of water soluble and oil soluble components in a stable creamy phase.

If improper emulsification is done or not done at all, then the product may end up separating with time, meaning that it will be a bad product in terms of texture. Through the high-end technology in emulsification, manufacturers guarantee that creams for the hair, such as shampoos, conditioners, and serums, feel silky.

Microbial Testing for Safety and Stability

On reaching this stage, the product is subjected to microbial test to ensure it has no sign bacteria or mold. This is a very important factor in ensuring that there are strict and quality inspection services rendered.

With the formula perfected, it’s time to prepare for packaging!

4. Semi-Finished Products and Packaging Process

At this point, the product is almost done developing, but there are two more crucial processes remaining.

Semi-Finished Product Testing

Prior to being distributed into bottles, it undergoes further testing. This helps ensure that the formula perfectly matches the specification and is also an additive one that does not change when manufactured in another batch.

Automated Filling Process for Precision and Speed

The Automated Filling Process checks that the bottle should contain the appropriate volume of the product that is required in a bottle. It cannot be underemphasized that the adoption of this newer innovation provides for leaner preliminary waste and enhanced production.

Capping and Batch Number Printing

Once the bottles have been filled, their caps are closed securely and each bottle labeled in terms of the batch number. This also makes it easy to monitor the time each product has taken and guarantee that every product can be traced back to the time of production.

Having the bottles sealed and labeled, they are now suitable to be shipped away!

5. Finished Product Packaging and Warehousing

Before the product is out in the market, final inspections and protective measures or packing have to be done at the factory.

Sealing and Protective Wrapping

All the bottles are also sealed with wrappers to avoid tampering during transportation to the respective destinations. Hair care product packaging enables the preservation of the hair care product and helps to prevent breakage, leakages, and contamination.

Final Inspection Before Shipping

The characteristics of these services can also be described as follows: Before the products are transported to their final customers, they undergo quality checks to ensure that they meet the required standard. It also means that the formula and packaging meet adequate standards regarding the industry.

Optimized Warehouse Management for Fast Delivery

Having an excellent storage system will involve ensuring that the products being stocked and stored are put in the right place and manner and are ready for dispatch as per the required schedule. Whether the order is for a saloon where the stock has to be replenished frequently or it is a large consignment for a large supermarket which restocking is done in bulk, proper storage system is important in preventing delay in delivery.

Conclusion

The hair care product process is a systematic flow of the product from the raw materials to the final product. In this process, the hair care manufacturer guarantees that from the Raw Material Testing stage up to the Automated Filling Process, every procedure undergoes thorough professionalism.

If you are a company involved in or planning to venture into the manufacturing of private-label hair care products, the best OEM/ODM manufacturing company will be ideal. This is because finding the right manufacturer can assist you in creating a hair care product that is unique among the rest.

Ready to Develop Your Own Hair Care Line?

If you are looking for a hair care product manufacturer that offers high-quality products with new dynamic features at higher productivity levels, we can assist you. Contact us now to embark on the creation of high-quality custom hair care products.

FAQs About the Hair Care Product Process

1. What is the hair care product process?

The hair care product process refers to the step-by-step production of hair care items, from sourcing raw materials to packaging and delivery. It includes ingredient selection, formulation, quality testing, and final packaging.

2. What is the difference between OEM and ODM in hair care manufacturing?

OEM (Original Equipment Manufacturer) allows brands to customize existing formulas, while ODM (Original Design Manufacturer) offers fully developed, ready-to-market products. Both options help businesses create private label hair care products efficiently.

3. How do manufacturers ensure product quality?

Manufacturers follow strict quality inspection standards, including Raw Material Testing, microbial testing, and stability testing, to ensure products are safe, effective, and meet industry regulations.

4. What is emulsification technology in hair care production?

Emulsification technology is a process that blends water and oil-based ingredients to create a smooth, stable texture in shampoos, conditioners, and serums. It prevents separation and ensures a high-quality final product.

5. What role does the automated filling process play?

The Automated Filling Process ensures that each bottle is filled accurately, reducing waste and improving efficiency. It also helps maintain hygiene and prevents contamination during production.

6. Can I customize my hair care formula?

Yes! Many hair care product manufacturers offer custom hair care products, allowing brands to create unique formulas with specific ingredients, scents, and textures tailored to their target audience.

7. How long does the production process take?

The timeline varies depending on the complexity of the formula, ingredient availability, and testing requirements. On average, the hair care product process can take anywhere from a few weeks to several months.

8. What types of packaging options are available?

Manufacturers provide various hair care product packaging options, including bottles, jars, tubes, and pumps. Packaging can be customized to match a brand’s aesthetic and functionality needs.

9. How can I ensure my hair care products are safe for consumers?

Partnering with a trusted hair care manufacturer that follows strict quality inspection standards ensures that all products are safe, tested, and compliant with industry regulations.

10. How do I start my own hair care brand?

To launch a hair care brand, work with an OEM/ODM hair care product manufacturer, choose a formula, design your hair care product packaging, and meet regulatory requirements. Many manufacturers offer full-service solutions to help you bring your vision to life!